The Dan Armstrong effects units were being produced in England by Wareham until 1977 as well as in the US by

Musitronics from 1976 to 1978 and from Beigel Sound Labs from 1980 to 1984. They were

also produced overseas shortly after Musitronics closed their doors. Craig Buzzart goes on to say "After Mutron

folded Joichi Yui (of the original Schecter Guitars and I had the Dan Armstrong effects boxes made in

Japan for a short time by the same manufacturer that made the Ibanez TS-808 Tube Screamer units" [Maxon]

"I wish I had one of those pedals as they were very well made, and are very rare."

Although the units sold well for a few more years by the late 1970s things soon began to slow down and before the

decade was out Wareham had ceased production. Years later Dan's son Kent acquired the registered trademark of the

Dan Armstrong sound modifier units with all rights and privileges and he began to produce the Dan Armstrong effects

himself.

Kent Armstrong states "when something is out of production for seven years the ownership of the trademark expires.

At that point, anyone in the world can acquire the trademark and do whatever they want with it. They can sit on it,

resell it, or use it. For example, WD Electronics is now the holder of the Stromburst instrument trademark as the latter had let it expire."

Kent continues, adding "when Wareham Electronics fell apart in the late 1970's - Dan owed them a lot of money so I

paid off the debts, and bought all the left over bankrupt stock as well as the remaining production parts in an attempt

to reintroduce the effects pedals that were laying in limbo." When asked why he bothered to remake Dan's pedals,

Kent stated "well, first off they are just very good sounding pedals, and I knew that they would sell pretty well.

Secondly, I wanted a chance to recoup the financial losses that I had incurred when I worked at the factory making the

Dan Armstrong 'London' instruments a few years prior." In an effort to help his father, and keep the factory

running, Kent had apparently been working with no compensation for some time.

Although Kent was legally within the law, and despite the fact that he had actually paid off a great deal of his

fathers debt - Dan was furious at him for taking such matters into his own hands. It would not be the first time that

the two would not see eye-to-eye and unfortunately, it would lead them to not speaking to one another for many years.

The first time was in 1977 when Kent tried to recoup the aforementioned financial losses by suggesting to his father

that together they reproduce the pickups that Dan and Bill Lawrence made for the Ampeg acrylic instruments as by this

point in time guitarists from all walks of life were seeking the various 'other' pickup models that the clear

instruments supported but did not ship with.

The proposal was for Kent to manufacture and distribute the pickups, and for using his fathers name they would split

the proceeds. Unfortunately it didn't work out - for Dan wanted an additional 10% above of the proceeds for the use of

his name. Kent goes on to describe "It just didn't seem right to me. I would have been doing all the work and Dan

would get as much - actually more for just using his name. It felt wrong and so I told him that I wasn't interested."

Kent then went on to make his own pickups using the name 'Rainbow Pickups' and once his name was more established, he

changed it to Kent Armstrong

Pickups. Unfortunately for many years these sorely needed pickups - made by Dan Armstrong & son never materalized.

|

The Dan Armstrong effects were made with original parts and left over stock, so they looked and sounded just like the

original Wareham units. However, before long some of the original stock parts were used up. One of the first such parts

to be exhausted was the actual various colored top pieces that houses the input jack and mini toggle switch.

Kent Armstrong goes on to say "After that, the units just had the name Armstrong on them." As can be seen at

left, are a few of these effects. Upon seeing the 'Armstrong' effects pedals once again being made, WD Electronics took

interest in the line and by 1990 had contacted and contracted Kent to eventually produce the effects for them.

|

|

|

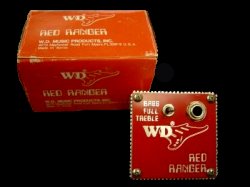

As can be seen above left & right, the effects units would retain their former names as well as their particular

and respective sound effect but the name on the top plates would now change. Naturally, WD choose instead to

put their business logo on the unit along with a decal of a Stratocaster scratchplate. Notice how

the boxes retain the look of the Wareham units with more interlocking tabs than the Musitronics units.

|

Soon afterwards, WD Electronics wanted to build cheaper versions of the effects units. Since Kent was busy making

his own pickups anyway, it was agreed to have the units made in a facility in Korea.

As seen at left, the units came with virtually the same literature as the original units along with the same type of

cardboard box, though these were different in that the boxes shared the same color coding as the unit that was

packaged within.

The made in Korea stamp is clearly visible on this Blue Clipper in the enlarged view on both the unit

itself, as well as on the outside of the box.

|

|

As seen at left, a WD Red Ranger. This one, like the Blue Clipper above is made in Korea. Notice the

matching color coded box that it shipped in. In this photo the colored box takes on more of an orange tint to it but

that may be due to it's age, or perhaps the lighting.

Again notice the additional interlocking tabs over that on the Musitronics units - making these effects more like the

original Wareham units.

|

As seen above. Sometime in the early 1990's Dan designed a newer, type of compressor/sustainer that he

called the Super Squeezer. Basically it is the Orange Crusher with a few modifications and the

literature that accompanies it states that it is "a 1990's version of the original compressor circuit for electric

guitar and bass which he made so popular in the mid to late 1970's."

Unlike the version before it, this unit was mounted inside the guitar control cavity and would call for a mini-toggle

switch to be installed on the instrument. Like the earlier units however, this on board circuitry utilized a 9 volt

battery - and the battery would then reside inside the guitars control cavity along with everything else. Care would

have to be taken to secure the battery down to keep it from shorting to any of the guitars circuitry.

The literature that accompanies these units also mention that "Power consumption has been reduced by a factor of 100

while the circuit gain has increased fourfold." These units were produced and marketed through the

Starr Switch Company

of San Diego, CA. which is still selling this unit, although their name has since changed to

Starr Labs. As seen at right, notice the reference

to the Orange Squeezer as their circuit board sits atop a cluster of oranges which acts as a backdrop for their packaging

back then.

continue

menu

Names and images are TMand © Dan Armstrong / Ampeg. All rights reserved.

All other names and images are TMand © of their respective owners. All rights reserved.

|

| |