As seen upper left & right, Ampeg advertizement brochures state that 'The body is carefully designed and balanced for maximum playing comfort'.

Matt Umanov goes on to say "I originally thought the body was going to be styled totally flat, much like a Les Paul Special - but once the guitar was

put together and slung on, Dan felt some contours were needed on the body - much in the same way that Fender Stratocasters and

Gibson SG's are."

"Dan was always one to delegate things out to others, and after looking it over he turned to me and said 'put in some contours to make

it more comfortable'....so.......... I did!." Once Matt had finished, the body featured several contours that makes it a very comfortable

playing instrument. Although thin, the body itself has weight (approx. 8.25) and is carefully balanced for playing comfort. It's weight is such

that it keeps the guitar from being "neck heavy" which is the achilles heel of many thin bodied guitars on the market.

As can be seen above, the contours that Matt had styled into the guitar body for maximum playing comfort. While it is

seen here from the backside, notice too the contouring of the top side of the body made obvious by the line that can

be seen extending down from the corner of the routed pickup channel, or scoop, to the bottom of the instrument, between

the two strap pins. This section of the body is shaved down in thickness just enough to allow for maximum comfort when

the arm is cradled over the instrument and in the playing position.

As Dan began to experiment with the electronics, he soon discovered that it was going to take much more in order to

obtain all the sounds he wanted the instrument to produce. After consulting more with Bill Lawrence, Dan decided that

a series of pickups to cover a wider variety of sounds would be made for the instrument.

Thus began the concept of the interchangeable pickup. Dan's first design called for a total of six pickups to be made

available for the instrument. Each pickup had a unique sound and were numbered 1 through 6. To remove the Rock Treble

pickup you would loosen the strings, and snap out the pickup, then insert the desired pickup you want, and finally

bring the instrument back up to pitch. After awhile Dan wasn't too fond of this method stating "more than anything,

the guitar was designed to be a players guitar, and a stage guitar. Loosening the strings and inserting a different

pickup like that was too time consuming. I needed something that wouldn't force a retune every time."

The ink was barely dry on the various Ampeg brochures & literature when Dan decided on a modification to the body.

To accommodate his interchangeable pickups without having to detune the instrument, Dan had designed a sweeping scoop

or channel to be routed out of the body whereby pickups could slid in and out at will, underneath the strings.

According to Dan "The body was machined in Ampeg's factory" and is a double cutaway design. When compared to the

prototype (seen in the literature in the 'Brochures' section) the guitar body had changed significantly. The guitar was

now machined with the aforementioned slide in pickup cavity, along with the tone & volume control cavity which now

featured, a sporty new set of male banana plugs on it to connect to the pickups as they slid into place. Then there

was a cavity for the 'ball-ends'of the strings to lie in, and lastly, a cavity, or channel for the neck to lay into.

In addition to the slide in pickup channel, the other big design change was the alteration of the lower cut-away 'horn'. It had been

machined slightly different from the upper horn, to accommodate the curvature of the wrist that would result when a player tries to

reach the upper registers of the fingerboard.

Former Ampeg engineer Steve Constantelos recalls the manufacturing of the body, stating "we would get these big

sheets of acrylic in from, I think Rohm and Haas. The sheets were similar to a 4'X8' sheet of plywood only thicker and much

heavier. I can't quite recall the actual measurements of the sheets but once they were delivered to us we would trace

and cut out as many bodies as we could from a sheet, so as not to waste much. Then we went to work machining them,

as well as sanding and polishing them out afterwards."

Steve continues, stating "it was a lot of work but it really wasn't messy like working with a wood body where you

have all kinds of wood chips and sawdust laying around. The stuff really didn't make much of a mess when being cut or

sanded, and we had tools with vacuum lines attached, which sucked up most anything in one's way when tooling. You

needed good tools to work with it, and even then we were all constantly sharpening our tools as acrylic dulled them

in no time."

At left one can see the cavities mentioned above. Note the slot, or cavity machined for the neck to fit into. Also the screw holes for the

scratchplate, as well as a hole for the pickup screw that secures the interchangeable pickups in place. Also, the differences in the

machining of the cutaway horns can be seen.

At the right, and as seen from the backside. It is here that the pickup screw gets inserted into the pickup once it is slid into place. Notice the circular,

indented, cone-shaped machining to keep the pickup screw flush with the back of the guitar. Four carriage type bolts get inserted into the back of the neck from

this side as well.

Bill Richardson pointed out something that I never noticed before. As can be seen in the upper left, the earliest

acrylic bodies were routed with a smaller, more shallow cavity for the ball end of the strings to lie into than later

models, seen at right. According to Bill "Dan had told me that players had complained that this cavity wasn't

routed deep enough nor wide enough for most players to easily attach the guitar strings. Actually this was a very

minor problem as all one must do is put a little bend in the string by the ball-end prior to installing a new string

and it will fit easily in the cavity. Still, Dan had respect for players opinions, and began to make this cavity a

little bit wider and deeper in the later models for players convenience".

Acrylic is also easy to maintain when it comes to scuffs. An early owners manual recommends a gentle buffing with

ordinary toothpaste and a soft cloth. The toothpaste acts like a mild abrasive and will eventually remove any scuffs, thus

keeping the body clear. "This" Dan once said "is the beauty of working with acrylic. On a regular guitar, if you

have a scuff you are stuck with it unless you refinish the entire guitar body. With my guitars you just buff away any

minor scuffs." However, for large area scuffs, or for full body polishing it is best when taken to a professional to be

buffed and polished out. The two phots below are courtesy of Mr. Bill Richardson.

At left, and as Bill Richardson states "The acrylic Dan Armstrong guitars lend themselves to a very fine and slow series of wet

sanding underwater. The bass body shown here is just partially wet sanded - to more/less show the actual process." Notice the

lower half of the body is sanded while the upper half is yet to be done. Also notice an original bass pickup that has gone bad, lying

next to the body with the resin removed from it. Since the pickup could not be repaired, Bill has submitted photos of it and it can be

seen in more detail in the pickup section.

At right.... Wow! What a difference! After the wet sanding process, Bill then used a three stage process to power buff it all out.

As seen here, the acrylic body has been restored to its original luster. Keeping a Dan Armstrong ∑ Ampeg instrument looking showroom new is

relatively inexpensive, and just one of the perks of an acrylic guitar body.

|

At left, Bill Richardson peers down the neck of a Dan Armstrong · Ampeg guitar after a good cleaning and buffing of

the acrylic body.

|

|

| .

At left, and right, a very early Dan Armstrong ∑ Ampeg guitar seen here sporting an ST pickup, which was obviously purchased later.

All photos of this instrument are courtesy of

HP.

|

| .

At left, and right, the smooth textured faux-wood scrathplate is consistent of an early model. Notice in both photos - a chipped off section

of the acrylic in the lower cut-away.

The owner looked all over the tongue of the neck looking for a serial number. When no number was to be found - he decided to break out a 'blue

light' as he suspected, judging by the look and feel of the tongue, that the serial number had been removed. According to him the blue light

definitely reveals that an abrasive, like sandpaper or something like it, had removed the serial number. The question is....... why?

|

| .

At left, and right, the headstock sports the Shaller tuners, again consistent with most of the earliest models.

|

| .

At left, and right, a smooth textured scratchplate, all chrome plated tailpiece, straight slotted tailpiece mounting screws and a rosewood

bridge with no fret across it - all typical of a very early model, with the exception of the ST pickup which Dan himself told me that he made

in 1970. Naturally it was acquired later.

|

| .

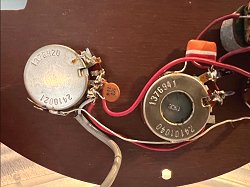

At left, and right, the orange/white/orange capacitor is a .033 microfarad Mullard tropical fish capacitor used in the earliest models. Across

the lugs on the volume control is a 500 picofarad capacitor used to maintain the highs (or treble) which is usually reduced when the volume

control is turned back, or down - also used on the earliest models.

The CTS volume pot reads a date of the 20th week (May 12-18) of 1969 - while the tone pot reads in at the 41st week

(October 6-12) of 1969 which would tend to suggest the instrument didn't leave the factory until later in October of 1969 at the earliest.

|

| .

At left, and right, one thing not consistent to this instrument is the case. As seen here this style of case came later. To read more about

the differences in cases over time visit the Dan Armstrong Registry

here.

But once again the question remains.... why a later made case? The owner makes an interesting case .... stating "I can't help but wonder if

this is 'Keef's' stolen Dan Armstrong guitar. How do you sell such a hot item as this? Easy, you sand off the serial number (done). Then you

trade or sell off the old original case and acquire a newer one (done). Last, but not least you pull out the prototype pickup, acquire an ST

or any other stock type pickup for it (done). As a result of these changes the instrument can be sold off as anything but a stolen guitar."

It's obviously a 1969 model, but if you go back up to the photos of the volume and tone pots you will notice the tone pot reads that it was made

in the 41st week of that year which is the week of October 6 - 12. The Rolling Stones tour in America officially kicked off on

November 7th of that year. It would be pretty tough to go from CTS making the tone pot to Keith Richards being on stage in America

just one month later - unless Richards and Wyman received their instruments later. However, by the 6th of December the tour in

America had ended - so the time frame seems a bit too tight.

Definitely an interesting hypothesis to be sure. Unfortunately It seems unlikely as the time line seem to narrow. I'm thinking that Richards

and Wyman's instruments were earlier instruments, likely at, or near the end of the prototypes. However, even as it stands it's still a really

nice instrument.

At left, today the Dan Armstrong · Ampeg clear acrylic guitar is on display in the Phoenix Musical Instrument Museum

which is the biggest museum in the world of its type including a collection of over 15,000 instruments from nearly 200 countries and territories in the world.

Other countries such as India, China, and Russia have multiple displays here as well, with subsections for different types of ethnic, folk, and tribal music.

Photo courtesy of Phoenix Musical Instrument Museum.

At right another Dan Armstrong · Ampeg model adorns the

Boston Museum of Fine Arts

collection where they state "By the 1960s

industrial designers had begun to incorporate acrylic plastics into the production of not only furniture, but also mechanical objects. The materialís transparent

quality shed light on previously unseen inner workings, allowing them to be perceived as part of the overall aesthetic. Guitar designer Dan Armstrong may have

conceived this clear acrylic guitar as a way of emphasizing the inconsequential nature of an electric guitarís body, as it has very little acoustical affect on the

instrumentís sound quality. The maple neck and rosewood fingerboard would have made the instrument feel more natural to players, but they also provide an attractive

visual contrast to the see-through body". Photo courtesy of Museum of Fine Arts Boston.

Naturally there are other electric instruments in most, if not all of these collections as well, but the inclusion of the Dan Armstrong · Ampeg

clear acrylic guitar serves as a lasting testament - and a reminder........ not only to current, but even future generations - as to the futuristic visions and

stylish design lines of Mr. Dan Armstrong.

continue

menu

Names and images are TMand © Dan Armstrong / Ampeg. All rights reserved.

All other names and images are TMand © of their respective owners. All rights reserved.

|

| |